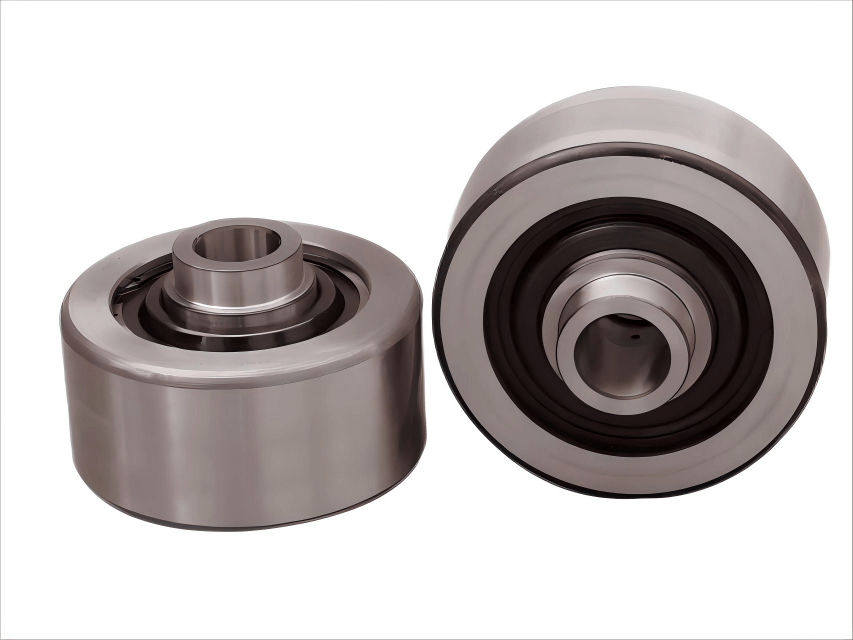

N28 Series Cylindrical Rollers Wheels for Conveyor Chains

N28 Series Cylindrical Rollers Wheels – Precision Components for Conveyor Chain Systems

Engineered specifically for the most demanding conveyor applications within metallurgical processing lines, our N28 series cylindrical rollers are manufactured to deliver exceptional performance reliability under extreme mechanical loads and challenging environmental conditions. The precision-ground cylindrical surface, achieved through advanced grinding technology, ensures ultra-smooth operational characteristics and significantly extended service life. These features establish the rollers as the premier selection for European industrial applications where uncompromising standards for quality, durability, and operational efficiency are paramount requirements.

Core advantage

- Heavy-Duty Construction: Featuring a robust design with reinforced core structure and high-strength alloy materials, these rollers withstand continuous high-load operations up to 28 kN in demanding strip and coil handling systems. The optimized wall thickness and stress distribution ensure reliable performance even under the most challenging industrial conditions.

- Enhanced Wear Resistance: Through-hardened bearing steel (HRC 58-62) combined with precision grinding to Ra ≤ 0.8 μm delivers exceptional abrasion resistance. This advanced material processing creates a uniform hardness profile throughout the roller, significantly extending service life in high-wear applications.

- Smooth Operation: Optimized dimensional accuracy with tight tolerance control (within ±0.05mm) ensures perfect concentricity and vibration-free conveyor movement. The precision-ground cylindrical surface maintains consistent performance characteristics, reducing noise and energy consumption while improving overall system efficiency.

- Reduced Maintenance: Extended service intervals of up to 50% longer than standard rollers, combined with easy replacement features including standardized dimensions and accessible mounting systems, significantly minimize operational downtime and maintenance costs.

Size:

G:19.2-41.75 mm

D: 85-175mm

CD: 133-306 kN

Core: 174-426kN

N series ball bearings for chain conveyors: low friction, high load-bearing capacity, long service life, and easy maintenance. Reliable industrial equipment solutions.

- Roller bearings do not use rolling elements such as rollers, cones, or spheres to roll on the support surface. This rolling action generates less friction, thereby reducing heat release, energy consumption, and wear. This design greatly reduces friction between moving parts and improves the efficiency of the equipment.

- High load-bearing capacity: Roller bearings can withstand high radial and axial loads. The radial load is perpendicular to the axis of rotation, while the axial load is parallel to the axis of rotation. The load-bearing capacity of roller bearings depends on their size, type, and material. Generally speaking, larger bearings can withstand higher loads than smaller bearings, while tapered roller bearings are more suitable for axial loads.

- Long service life: Roller bearings are designed to have a long service life even under high loads and harsh conditions. They are made of high-quality materials that are wear-resistant, corrosion-resistant, and fatigue resistant, such as chromium steel, stainless steel, or ceramics. In addition, they are equipped with precision machined components that provide ideal positioning and alignment, reduce stress, and extend the service life of bearings.

- Easy maintenance: Compared with other types of bearings, roller bearings do not require special maintenance. They are customized, which means they can compensate for slight twisting or bending of the shaft without damaging the bearings or machine. Roller bearings also have detachable seals or protective covers for easy cleaning and lubrication. These advantages make roller bearings an ideal choice for equipment such as chain conveyors, which can improve work efficiency, extend equipment life, and reduce maintenance costs.