Flying Shear Technology for Metal Processing

Our flying shear systems revolutionize metal processing with high-speed, accurate cutting capabilities that operate seamlessly in continuous production lines.

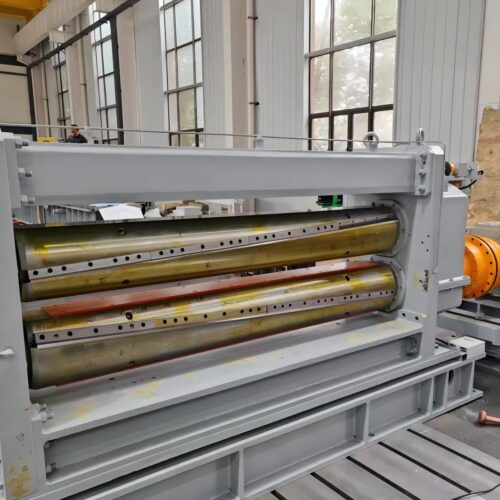

Flying Shear Technology:

Revolutionizing metal processing with our advanced flying shear technology, we deliver precise and efficient cutting solutions engineered specifically for continuous steel rolling production. Our equipment performs high-speed, ultra-precise cutting of both head and tail sections of moving metal strips while enabling seamless horizontal cutting operations – all without interrupting production flow. This innovative approach ensures exceptional dimensional accuracy, minimizes material waste, and maintains uninterrupted manufacturing continuity, setting new standards for efficiency in modern metallurgical operations.

Main advantages:

- Maximum Performance Capacity: Engineered to perform cutting operations at full production line speeds up to 300 m/min without requiring process deceleration or stoppage. The system maintains perfect synchronization with continuous material flow, eliminating production bottlenecks and maximizing throughput in high-volume manufacturing environments.

- Exceptional Cutting Precision: Utilizing advanced servo-driven synchronization technology that precisely matches tool velocity with strip movement, achieving cutting accuracy within ±0.5mm tolerance. This precision engineering ensures consistent dimensional compliance and eliminates secondary processing requirements, even at maximum operational speeds.

- Optimized Cost Efficiency: Dramatically reduces material waste through precision cutting patterns and minimized kerf loss, while lowering maintenance expenses through robust component design and accessible service features. The system’s operational reliability further reduces costs associated with unplanned downtime and production interruptions.

- Comprehensive Material Versatility: Designed to process diverse metal specifications including ferrous metals (carbon steel, silicon steel), non-ferrous metals (aluminum, copper alloys), and stainless steel grades (200, 300, 400 series). Quick-change tooling and adaptive parameter settings enable rapid material transition without compromising cut quality.

- Advanced Automation Integration: Features seamless integration capability with Automated Control Systems (ACS) through standardized communication protocols (PROFIBUS, Ethernet/IP). The intuitive programming interface allows straightforward configuration of cutting patterns, length parameters, and production schedules for complete operational automation.

Working principle and our technological innovation:

Our flying shear adopts radial kinematics or disc scheme to synchronize the linear velocity and angular velocity of the tool with the speed of the moving workpiece at accurate times.

Our solution features:

- Intelligent Control System: The integration of high-precision servo motors with advanced PLC (Programmable Logic Controller) creates a fully synchronized control system that maintains exceptional accuracy throughout all operational phases. Utilizing real-time feedback mechanisms and adaptive algorithms, the system ensures precise velocity matching and position control with response times under 10ms, achieving synchronization accuracy within ±0.1° while providing comprehensive monitoring and diagnostic capabilities for optimal process control.

- Robust Structural Design: Engineered specifically for demanding metallurgical workshop environments, the equipment features a heavy-duty framework constructed from high-strength steel with reinforced welding techniques and stress-relieved components. The design incorporates vibration-dampening properties and thermal stability characteristics to withstand continuous operation under extreme conditions including temperature variations up to 45°C, particulate contamination, and mechanical shocks common in industrial metal processing facilities.

- Adaptive Integration Capability: Our solutions employ modular design principles and standardized interface protocols that enable seamless integration into both newly constructed production lines and existing facility upgrades. The system’s flexible configuration options and scalable architecture allow for customized implementation without requiring extensive modifications to current infrastructure, supporting quick installation and commissioning while maintaining full compatibility with various production line layouts and material handling systems.

Application areas:

Our flight shearing technology is highly suitable for the following fields:

- Steel rolling units (hot and cold rolling).

- Steel bar and profile production.

- Strip and metal strip production lines.

- Nonferrous metal processing (aluminum, copper).